How to use FloraPro®

The FloraPro® system is easy-to-use and efficient for the commercial production of a wide range of indoor-and greenhouse-grown plants.

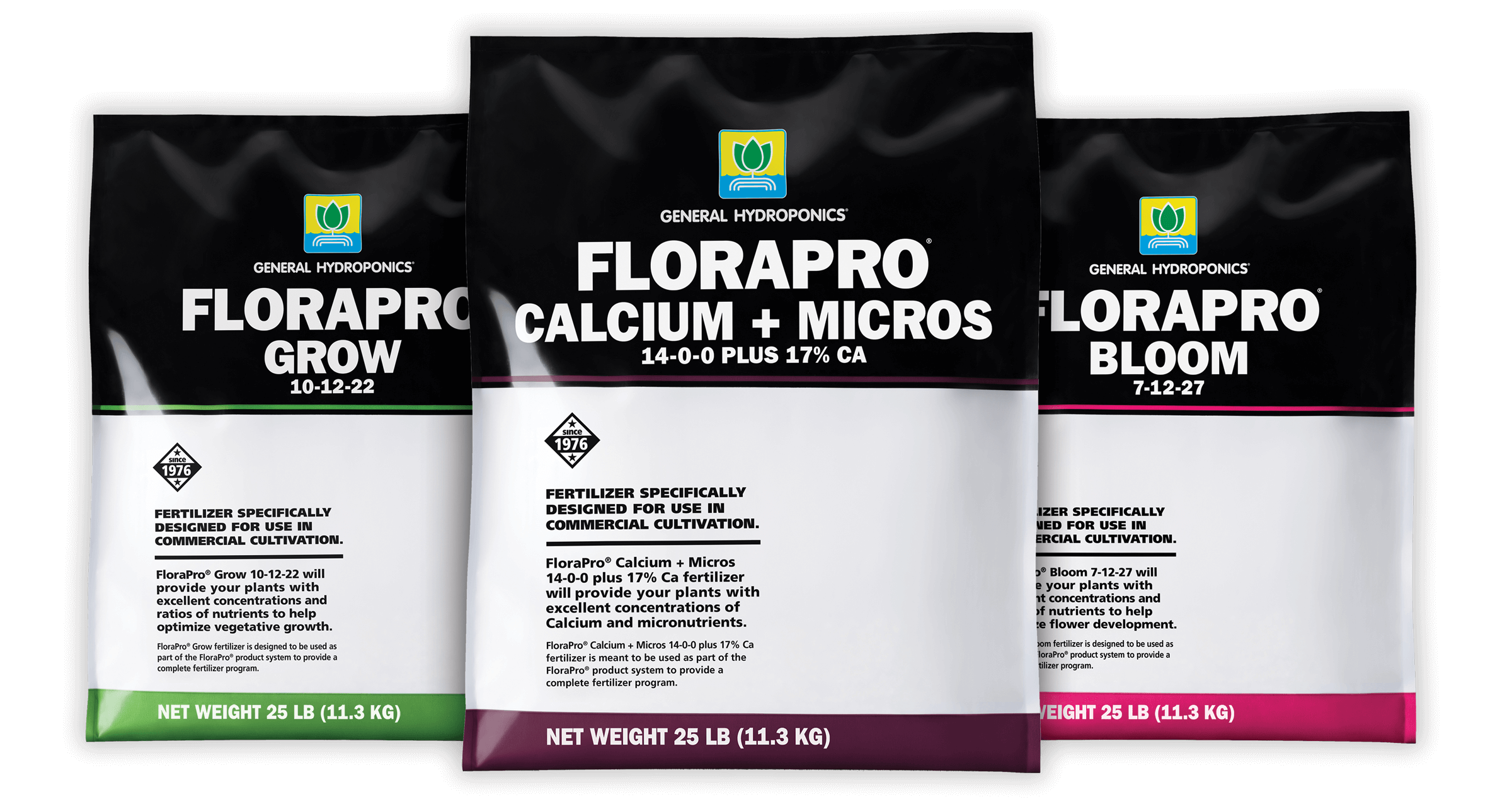

As a two-component system (also known as an A/B system), it is made up of two parts: A fertilizer containing Nitrogen, Calcium, and micro elements (we call it A, part A, tank A or Calcium + Micros) and an NPK plus magnesium and sulfur component (we call B, part B, tank B or NPK). This two-part system provides robust and effective nutrient delivery to plants.

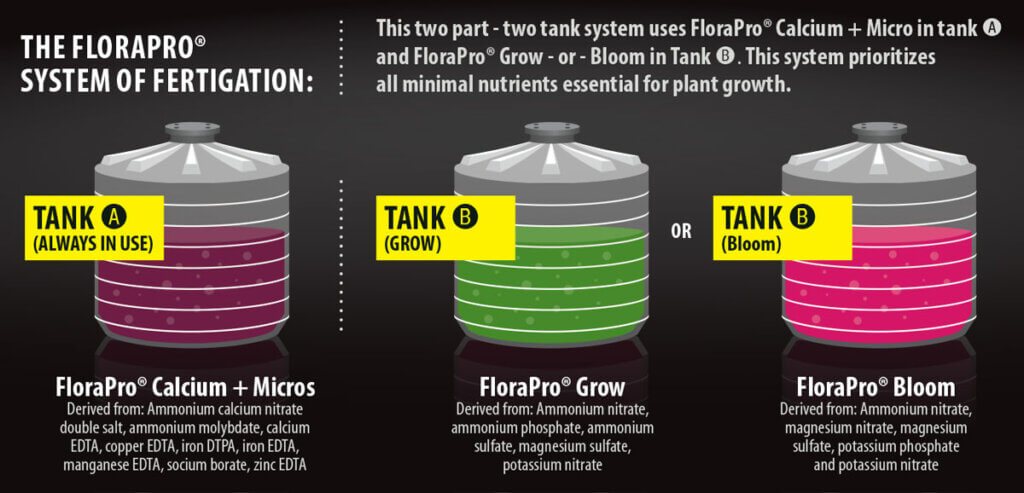

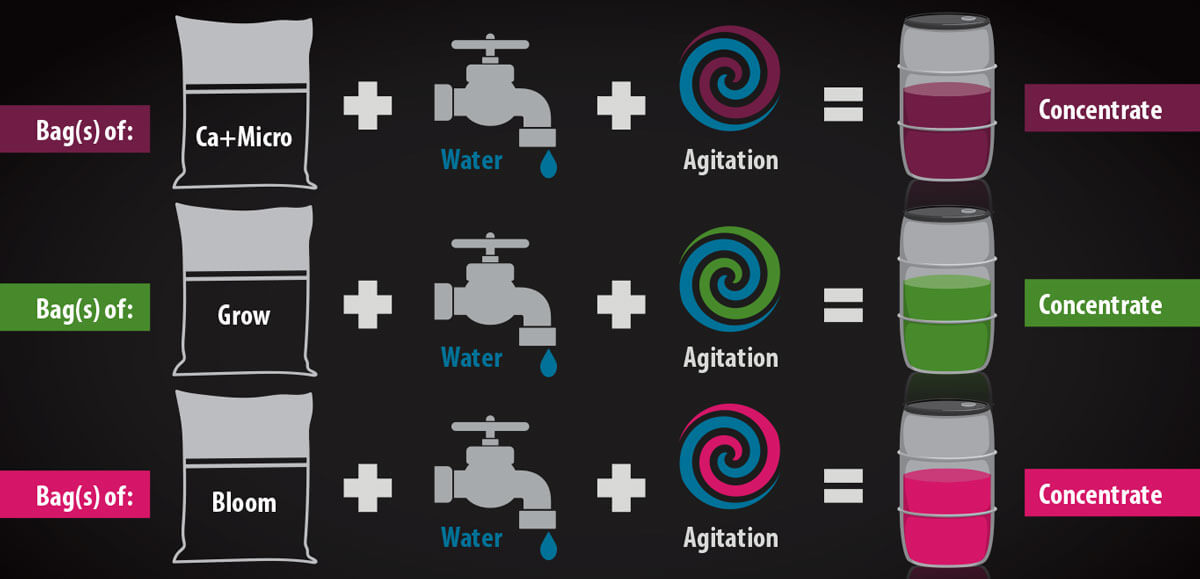

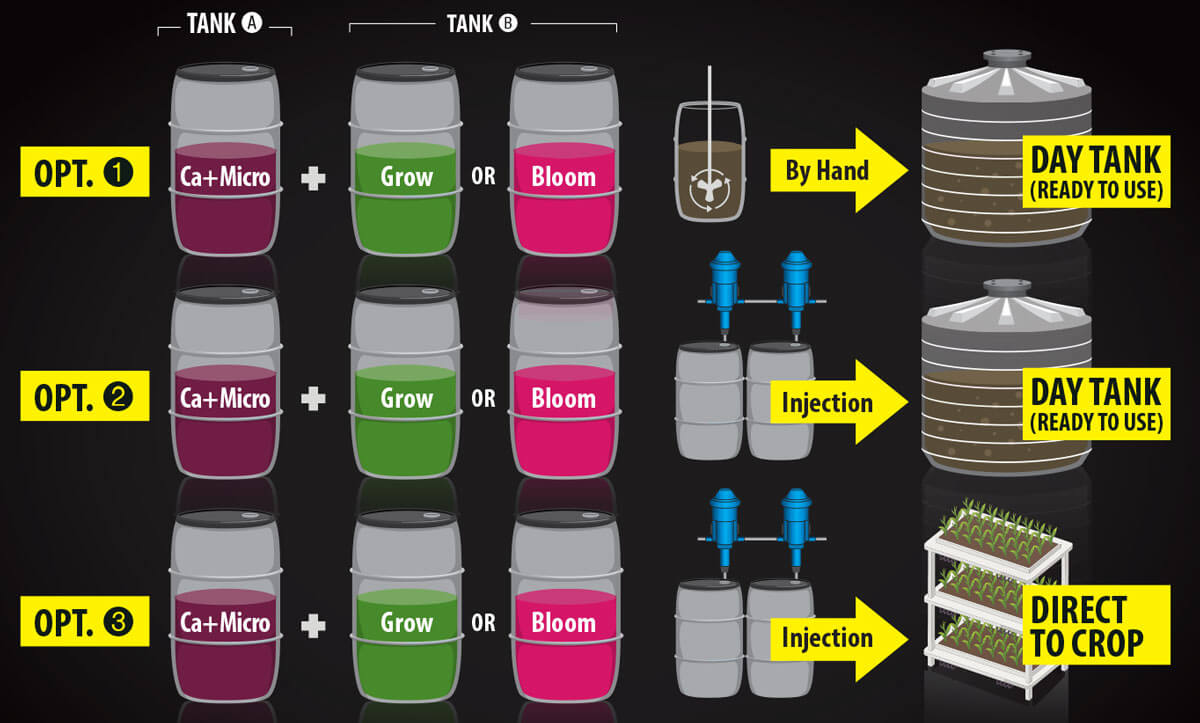

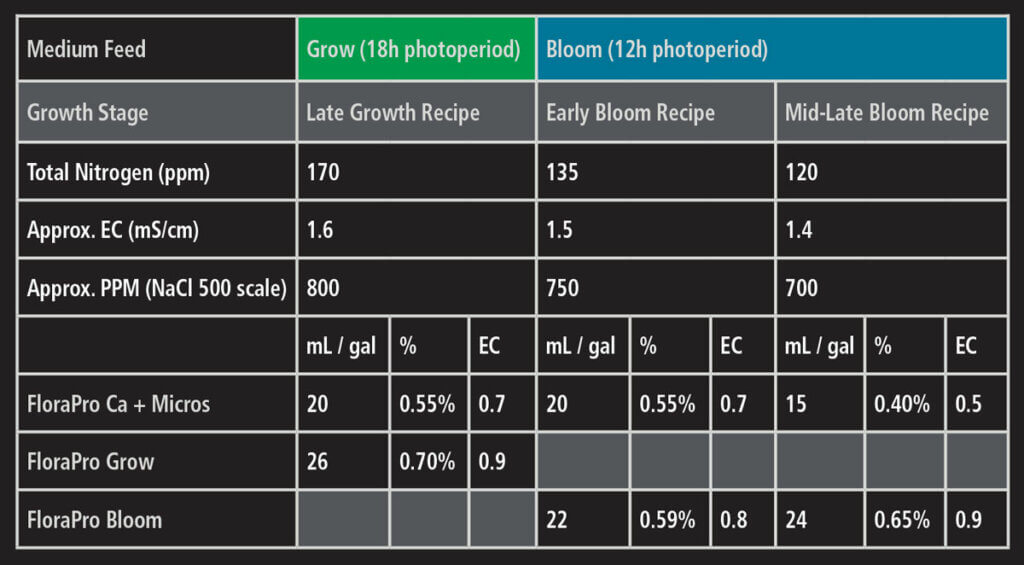

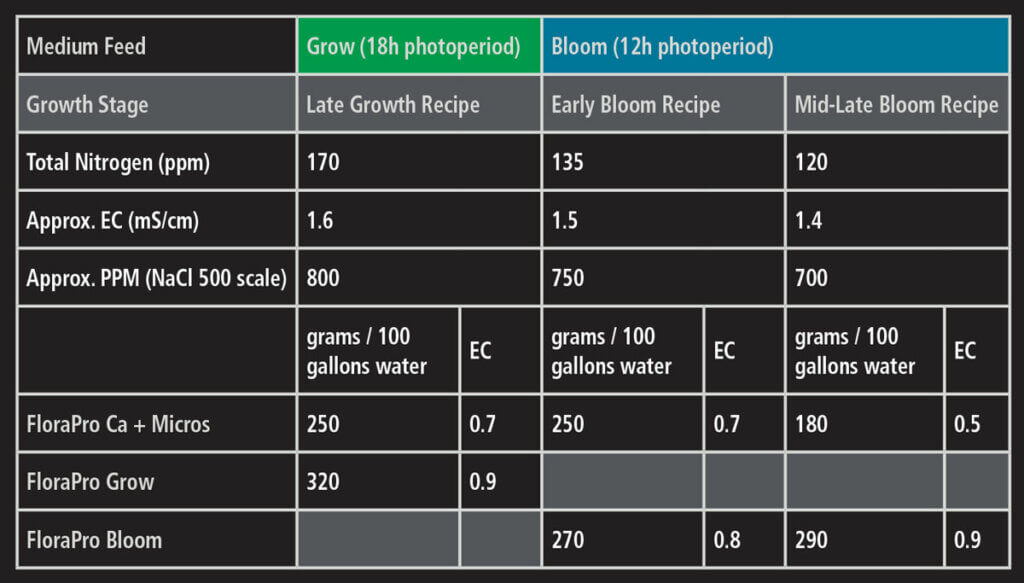

As shown in Figure 1. The FloraPro® product system includes the use of FloraPro® Calcium + Micros in Tank A and either FloraPro® Grow or FloraPro® Bloom in Tank B, depending on the growth stage of the crop. When plants are in a vegetative stage, use our FloraPro® Grow formulation. When plants are in their flowering stage, use the FloraPro® Bloom formulation.

How to dissolve FloraPro® fertilizers for commercial use

FloraPro® is a water soluble fertilizer, meaning it is concentrated powder and must be dissolved in water prior to use. Depending on the cultivator, there are a few general approaches:

Direct Addition

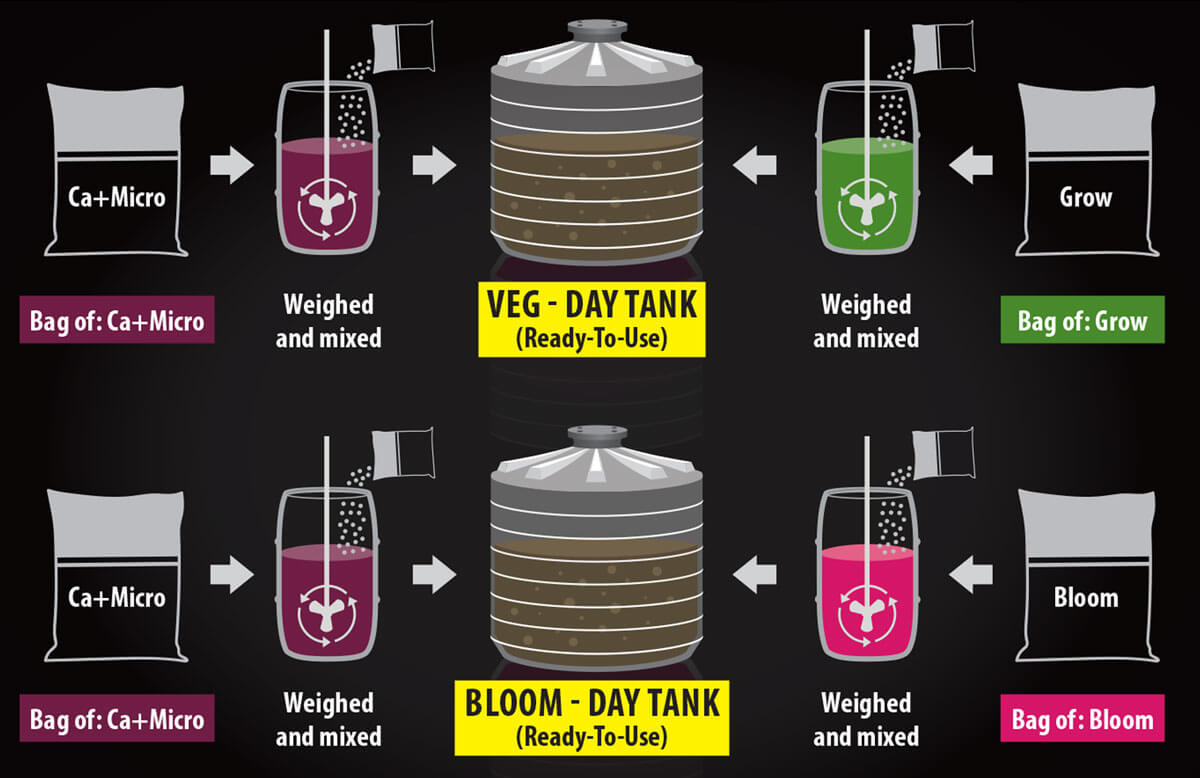

Preparing “ready-to-use” nutrient solutions stored in a tank system. This is often called a “day tank” system. The FloraPro® product is dissolved directly into solution in the day tanks. Typically, there are day tanks for specific growing areas in the operation OR for various stages of the crop. At the simplest form, there may be a day tank for the vegetative stage and a day tank for plants in the flowering stage. This would require the usage of the ‘Direct Addition’ feed charts which are in grams per liter or grams per gallon.

Note: Always mix each individual FloraPro® product in its own tank prior to adding to the ’day tank’

Tips for direct addition:

- It is very important to accurately weigh the amount of fertilizer to be added each time.

- For best results in large day tanks (>150 gal), dissolve the FloraPro® to be added in a smaller container or bucket and then add this solution to the larger day tank.

- Never mix any of the FloraPro® products together in a concentrated solution

- Always triple-rinse the container used between products, or have dedicated containers for each product.

- As with other methods, using warm water to dissolve the product will speed up the process.

A note about using day tanks in an operation

As mentioned above, it is common to have more than one day tank in a facility. The number of day tanks will often depend on the complexity of the system and size of the facility. There are two main ways that growers will break down how their day tanks are laid out:

Often in smaller operations, there may be one day tank per room or bay area. This means that the recipe in that tank will change as the crop progresses and grows. This gives growers great control over knowing exactly what is going into a given room at any time as it is a simple 1:1 ratio of rooms to tanks.

However, as the number of rooms increases, and the stage of crop growth is staggered across those rooms it may become economical to have one tank per recipe rather than per room. A common configuration is where there is a day tank for the Vegetative phase, Early Bloom Phase, Mid Bloom Phase, Late Bloom Phase, Ripening and any “Flush” phase. The plumbing will be such that any recipe is able to be fed to any room.

While we provide suggestions on recipes for these various stages, it is important that growers monitor their crops to assess if they need to vary the nutrients provided based on their conditions such as crop type / variety, light intensity, duration and quality, temperature and humidity settings, carbon dioxide usage, growing media used, container size and irrigation methods.

Concentrate Tanks

This method involves preparing a concentrated “stock solution” for further dilution by hand or using fertilizer injectors or dosing systems.

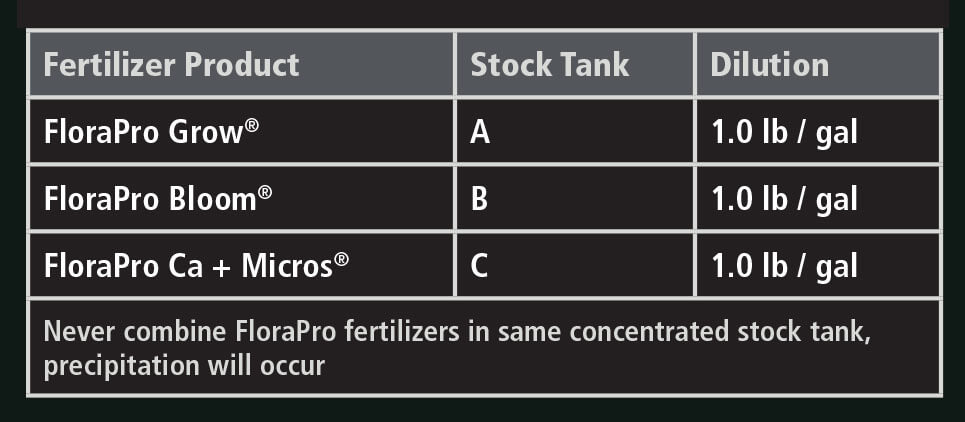

Many cultivators choose to prepare a concentrated stock solution, as this method provides the ultimate in nutrient uniformity and ease in handling. The concentrations used may vary but we recommend a rate of 1 lb of product per gallon of end solution.

Once a concentrate tank has been prepared for each FloraPro® product it can be used exactly like any other liquid concentrate solution (eg. Flora® Series). This means that growers can:

- Dilute the concentrates by hand into a day tank

- Utilize a fertilizer injection system to fill day tanks

- Utilize a fertilizer injection system, inject fertilizer in-line for direct application to the crop with no day tank

When using fertilizer injection systems

Fertilizer injection systems dilute concentrated stock solutions into irrigation water at a set rate (or dilution ratio) during the irrigation process for convenient fertilization of crops.

There are two approaches to using fertilizer injectors:

- Setting the amount of fertilizer constant to make a concentrated stock solution and varying the injection ratio to achieve the targeted final amount. Most cultivators use either 1 or 2 pounds (lbs) per gallon of concentrated stock solution. This is the most common method for indoor production that requires many fertilizer recipes.

- Setting the injection ratio constant and varying the amount of fertilizer used to make a concentrated solution to achieve the targeted final amount. Most growers use a ratio of 1:100 (1%) or 1:200 (0.5%) in their systems although there are other more sophisticated systems that can vary the rate of dilution over a wide range of dilution ratios either manually or automatically. This is most common in ‘traditional’ horticulture and greenhouse production.

Use the information in Table 3 to confirm how much FloraPro® fertilizer to dissolve per gallon of stock solution to achieve a desired final nutrient concentration.

A note on measuring concentration:

You will note that concentration in our charts is expressed in ppm Nitrogen (N). This is because traditionally, most water soluble fertilizers (WSFs) are used in this way, given that nitrogen is the key nutrient driving plant growth. However, we also cross-reference the ppm N level to the theoretical conductivity level of that solution, expressed as mS/cm and/or PPM (using the 500 ppm NaCl standard). This is to help the grower easily verify the estimated concentration of the solution made, regardless of the conductivity meter used.

FloraPro® is a two-tank system

The great thing about the two-part (or two-tank system) is that either component can be adjusted accordingly to meet the needs of the crop.

However, please be advised that each FloraPro® fertilizer (i.e. Calcium + Micros and Grow or Bloom) MUST be diluted with water separately and kept in separate stock tanks for use with direct-injection systems. Refer to Figure 1 for a standard FloraPro® injection configuration. Allowing concentrated solutions of FloraPro® Calcium + Micros and FloraPro® Grow or Bloom to mix will result in nutrient precipitation, which may clog or damage irrigation equipment.

How to prepare a stock solution

- In clean stock tank, use fresh water to fill roughly to 70% of desired volume. RO water is preferable but not required. Hot water will greatly speed up the dissolution process.

- We recommend using a paddle mixer or equivalent mixer to agitate stock tanks while adding FloraPro® fertilizer.

- Slowly add the specified amount (weighed out, or number of bags) of FloraPro® fertilizer for the targeted stock solution volume to achieve your desired concentration.

- Once the desired mass of FloraPro® fertilizer has been added, fill the stock tank with water to reach the final targeted stock solution volume.

- Stock solution will be ready to use once the product is dissolved. There may be a slight amount of turbidity at high concentration levels. This is not unusual.

- Time required to fully dissolve will vary depending on water quality, temperature and agitation.

- The stock solution does not need to be agitated once FloroPro® is solubilized, although agitation during injection will provide the ultimate in uniformity. Agitation can be done by using a mechanical device or a submersible air or water pump (protect submersible pumps from corrosion).

- It is generally recommended to cover the concentrated solution to avoid evaporation

and keep in a cool, dry place out of direct sunlight. It’s recommended to use a

concentrate, stored properly, within 2 weeks of preparation.

Example: to mix 2 bags of FloraPro® at 1 lb / gallon of concentrate volume a grower will first fill their clean stock tank to approximately 35 gallons with hot water (remember: 1 bag is 25 lbs, and so the volume at the end will be equal to 50 gallons, because 2 bags x 25 lbs = 50 lbs.). The grower then adds both bags of FloraPro® and agitates the solution. After the product has dissolved, they top up the tank to the final volume of 50 gallons.

Tips and tricks when preparing stock solutions

- RO water is preferable but not required.

- Hot water will greatly speed up the dissolution process.

- We recommend using a paddle mixer or equivalent mixer to agitate stock tank while adding FloraPro® fertilizer. Assure the equipment submerged into concentrates are resistant to corrosion.

- It is always a good idea to check that the concentrated stock solution was prepared properly. This can be done by diluting a small amount of concentrated stock solution and checking EC. For example, to dilute the concentrate 1% (1:100), then measuring EC.

- FloraPro® bags are 11.3 kg (25 lbs). For those without the means to weigh a large amount of fertilizer, use this measurement to make stock solution based on the number of bags needed. For example, when using a 55 gallon drum, mix 2 bags (50 lbs) with the required water to obtain a TOTAL of 50 gallons of solution. This will achieve a 1 lb/ gallon concentrated stock solution. Or if you are using 5 pound bags, you may dissolve the contents of a 5 lb bag in a 5 gallon bucket assuring that fertilizer and water make a total of 5 gallons finished concentrate.

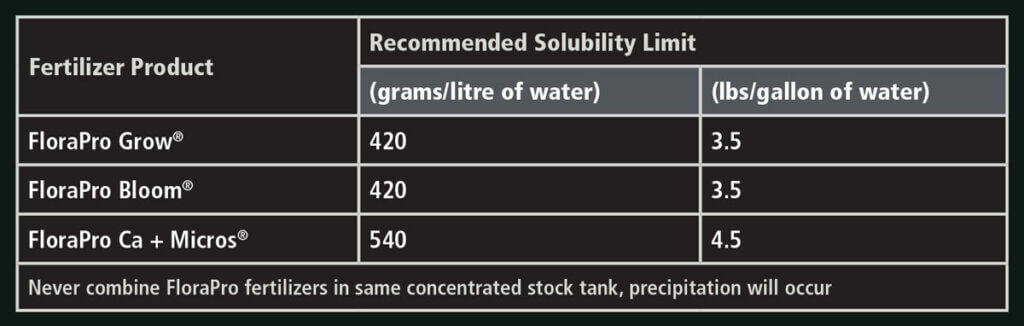

- Keep in mind the solubility limits of each Fertilizer. We recommend never exceeding 80% of the max solubility of each fertilizer. The more concentrated the fertilizer, the longer it takes to fully dissolve when preparing the stock solution.

Recommendations for storing Florapro®

FloraPro® is a blend of high-quality mineral salts, and is made with internal good management practices to achieve excellent quality standards. To maintain excellent quality, store as follows:

- Store fertilizer in a cool, dry place out of direct sunlight.

- Avoid high temperatures or high humidity to prevent fertilizer from liquifying or clumping.

- Product is hygroscopic. Opened bags should be closed tightly and stored in airtight containers to prevent hardening.

Solubility limit of FloraPro® fertilizers

The following represents an example feed program. For expert growers, go to the feedchart resources page to customize the perfect feed program for your specific needs.

Example dilution table using 1 lb / gallon stock solutions

1 lb / gallon stock solution dilution table

1 lb / gallon commercial feedchart: for fertilizer injectors

Feedchart for day tanks or reservoirs

Feeding charts are recommendations only. Adjustments may be needed based upon environmental conditions, individual grow structure, and use of additional products. Actual results may vary.

When using another injection ratio, the amount of FloraPro® will need to be adjusted to reach the correct targeted final nutrient values. For example, if a 1:200 ratio is used, then you will need to double the amount of fertilizer dissolved to prepare the concentrated stock solution.

Water Quality is the Key!

The first step is to determine the rate of FloraPro® Calcium + Micros. To do this, the first step is to consider the water quality intended to be used on the crop.

Experienced indoor growers know to use RO (reverse osmosis) treated water to consistently minimize the mineral content of the water and filter out unwanted contaminants. However, some cultivators may be using untreated municipal or well water sources. In this case, a water quality analysis is recommended since water will contain various elements such as calcium, magnesium, sodium, chloride or boron and also, components that will affect growing medium pH control such as bicarbonate and carbonates which may be expressed as alkalinity.

If water quality is poor, a Hydro-Logic® RO system can help to ensure filtered water is delivered to your plants. However, waters having a mild amount of minerals and alkalinity may just require an adjustment in the use rate of FloraPro® Calcium Plus Micros compared to standard rates using RO water (which are described in our feed charts). Regardless, please contact Hawthorne and we can assist with having your water tested and any recommendations based on the analytical results.

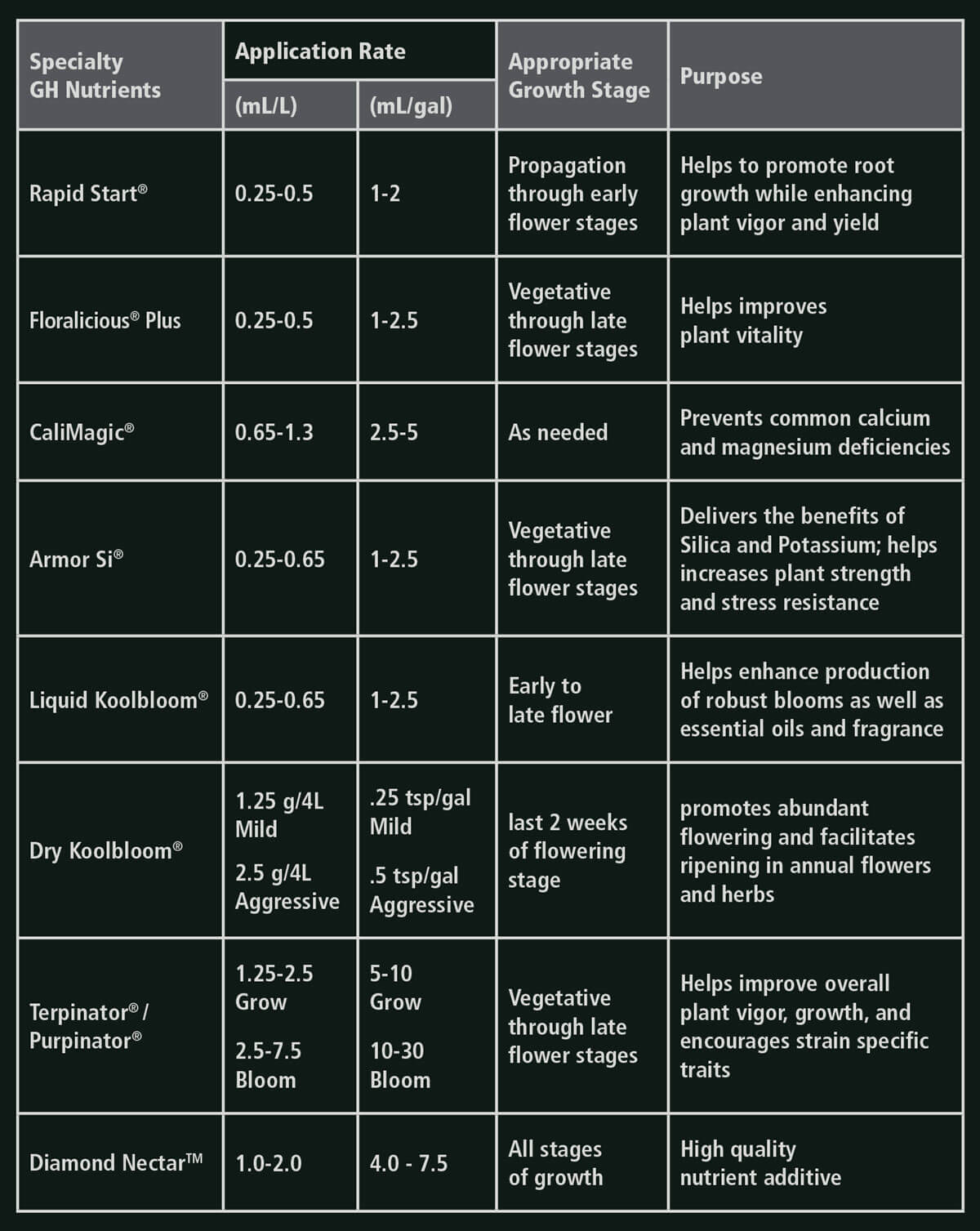

Recommended specialty nutrients

Hawthorne manufactures other General Hydroponics® nutritional products that may be used in combination with a FloraPro® program. Table 5 lists the various products available, along with their recommended rates of application. Refer to the products’ specific labelling directions for further information. For additional support, contact Hawthorne Technical Support or Professional Technical Services.